SPINNING CANS

MADE IN ITALY

We are the leading innovators in spinning cans: our experience produces the finest products for both Italian and international spinning mills.

QUALITY NEVER LOSES ITS THREAD.

Metal Lastra’s spinning cans are renowned for the superior quality

they are known for in the final product. They are the ideal choice for

spinning mills aiming to reduce costs and optimize production.

We design each spinning can in-house, tailored to the type of yarn

and the plant’s capacity, calibrating the spring to keep the thread at

maximum efficiency without the risk of breakage.

Studies conducted by the Ahmedabad Textile Institute have confirmed that 3 cm of imperfections in the raw yarn correspond to 3 meters of imperfections in the final yarn. For this reason, it is essential for spinning mills focused on quality to choose the right product that supports their yarns and optimizes both production and yarn quality.

SPRINGS

Our self-centering springs aim to provide stability and consistent

performance, keeping the yarn level and always at the right height to

avoid fraying.

Thanks to their design, no cords are needed—the spring remains

stable without exerting excessive tension on the yarn during loading

and unloading of materials.

Over the years, we have continuously worked to improve our flagship

product, the Spinning Cans, enhancing and making our production

process increasingly unique.

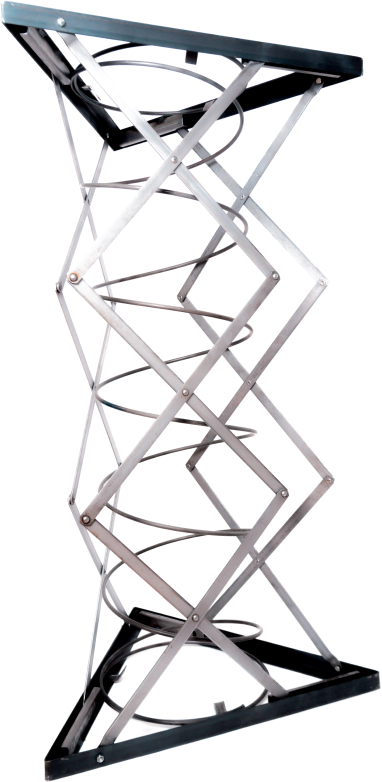

PANTOGRAPHS

Our Pantograph, available for spinning cans with diameters ranging

from Ø24” to Ø1400, is made of iron to provide stability, strength,

and consistent performance, even with increasing loads and

diameters.

Thanks to the perfect combination of spring and pantograph, we help

maintain the constant and precise alignment of the top plate, which

contributes to the quality of the yarn during various production

processes.

METAL COMPONENTS

They are made of galvanized steel for high resistance to corrosion

and scratches. We select only the highest quality materials to

support the long life of our spinning cans.

HDPE SHEETS

The body of the spinning can is made of high-density polyethylene

(HDPE), a material that combines lightness, strength, and a smooth

surface, promoting durability and consistent performance over time.

Thanks to the inclusion of antistatic agents, the material minimizes

the accumulation of dust and dirt, maintaining a clean appearance

and enhancing the overall efficiency of the production process.

HDPE TOP PLATES

We have tailored our plates for every type of processing, making

them ideal for both delicate materials and the latest high-speed

coiler models. To promote greater durability, we have selected a

highly resistant HDPE, less prone to breakage.

WHEELS

Closa castors, featured in our spinning cans, represent the top

choice for outstanding performance and reliability. Maintenance-free

and lubrication-free, they are designed to provide excellent stability

and effortless handling, making them ideal for applications on

smooth and even surfaces. Designed for efficiency and durability in

the most demanding environments.

Thanks to these qualities, Closa castors have quickly become a

benchmark in the yarn manufacturing industry, recognized as an

industrial “standard of excellence.”

We strive to meet all customer needs, which is why we offer an

additional option. Standard wheels are designed to perform on all

types of terrain and surfaces, offering the perfect balance between

load capacity, smooth rolling, and abrasion resistance. A versatile

and dependable solution for a wide range of operational

requirements.

FAQ

Your questions, our answers

Scroll through the list if the answer you are looking for already exists.

Which accessories can be added?

Upon request, handles, bumpers, and kicking bands can be included.

How are the spinning cans shipped?

Upon customer request, the vases can be shipped assembled or disassembled. In the latter case, assembly by the customer is quick and easy and everything necessary is provided.

What diameters are available?

From 225 mm diameter up to 1600 mm diameter.

What do I do if I need spare parts?

You can order spare parts for all components of the spinning cans purchased. Fill out the form on this page!

REQUEST INFORMATION

ON METAL LASTRA PRODUCTS

To receive information, catalogues, quotes or any other request, fill out the form below.

We will get back to you as soon as possible.

info@metallastra.com

+39 0331 567781

Via M. Venegoni, 55 – 20038 Busto Garolfo (MI) – Italy